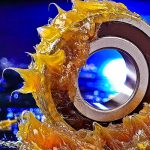

What is Industrial Oil?

Industrial lubricants are basically defined as compounds like fluids, greases and oils. They are used in order to lessen wear and tear of materials while reducing binding and friction. In some extreme cases, they may also prevent or lessen electrical resistivity while it increases thermal conduction. Those products are ideal because they can prevent corrosion in both the inner and outer surfaces where they are applied.

Industrial oils help the necessary equipment to run smoothly, even in the most difficult environments, and for long periods of time insuring the quality, sustainability and giving you improved reliability.

Another valuable quality of industrial lubricants which is highly utilized is ability to carry thermal energy for various applications such as metal working, machine cooling and process heating. We can summarize the industrial functions as;

- Lubrication: Control of friction and wear by reducing friction between surfaces in mutual contact.

- Heat Transfer: To cool the moving parts and surfaces with heat transfer.

- Sealing: Prevent of leakage between moving parts.

- Surface Protection: Lubrication film supply a surface protection.

- Shock Absorber: Reduce and eliminate the shocks from mechanical force on moving or fixed parts.

- Mass Transfer: Able to suspend and carry the particles from wear fuel decomposition, oil, sulfur and dust and so on.

- Power Transfer and Supply Pressure: Most important functions in hydraulic oils.

Another valuable quality of industrial lubricants which is highly utilized is ability to carry thermal energy for various applications such as metal working, machine cooling and process heating. We can summarize the industrial functions as;

Packing

- Drums (208 Lt.)

- Plastic/Steel Pails (20 Lt.)

- Plastic/Steel Gallons

- Steel Cans